In the high-stakes arena of advanced materials, Japanese conglomerate Toray Industries is accelerating its carbon fiber innovation at a pace that signals a strategic shift in global manufacturing dynamics. Long recognized as the world's largest producer of carbon fiber composite materials, Toray is not merely iterating on existing technology but is spearheading a fundamental transformation in how these materials are conceived, manufactured, and deployed across industries from aerospace to automotive and beyond.

The impetus for this acceleration is multifaceted, driven by intensifying global competition and soaring demand for lightweight, high-strength materials in the pursuit of sustainability. For decades, carbon fiber has been the material of choice for applications where performance trumps cost, most notably in military and commercial aerospace. However, the landscape is changing rapidly. The urgent global push for decarbonization, particularly in the transportation sector, has created an unprecedented demand for materials that can significantly reduce the weight of vehicles, thereby cutting fuel consumption and emissions. Toray, along with other Japanese leaders like Teijin and Mitsubishi Chemical, is responding to this call not as a passive supplier but as an active architect of the next industrial revolution.

At the heart of Toray's strategy is a deep, sustained investment in research and development that targets the traditional bottlenecks of carbon fiber production: cost and throughput. The conventional process for producing carbon fiber—precursor synthesis, oxidation, and carbonization—is energy-intensive and time-consuming. Toray's latest breakthroughs, though closely guarded, are understood to focus on novel precursor materials and advanced manufacturing techniques that slash both energy consumption and production time. The company is moving beyond the standard polyacrylonitrile (PAN)-based precursors, experimenting with lower-cost alternatives that do not compromise the legendary tensile strength and modulus that have made its TORAYCA® brand synonymous with excellence. The goal is clear: to bring the cost-performance ratio of carbon fiber into a range that makes it viable for mass-market automotive applications, a market segment that has long been the holy grail for materials scientists.

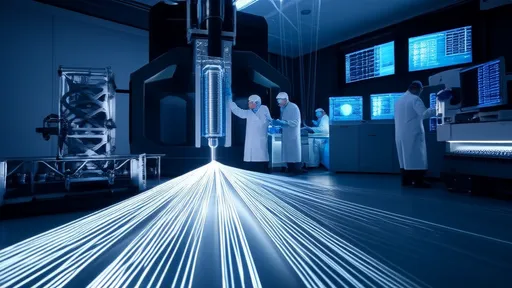

This technological push is not occurring in a vacuum. It is being supercharged by the digital transformation of manufacturing. Toray is integrating artificial intelligence and machine learning into its production lines to create "smart" carbon fiber. By deploying vast networks of sensors and leveraging big data analytics, the company can now monitor the production process in real-time, predicting and correcting microscopic inconsistencies in the fiber that would have previously gone undetected until the final quality assurance stage. This results in a more consistent, higher-quality product and a dramatic reduction in waste, further driving down costs. The move represents a paradigm shift from a chemistry-led process to a data-driven one, ensuring that every strand of fiber meets exacting specifications for its intended application, whether it's for a Boeing 787 Dreamliner or the latest hydrogen fuel cell vehicle.

Furthermore, Toray's innovation extends beyond the fiber itself to the very way it is integrated into final products. The company is pioneering new approaches in design and pre-forming. Traditionally, one of the most expensive aspects of using carbon fiber composites has been the labor-intensive process of laying up the fabric and impregnating it with resin. Toray is developing advanced pre-preg technologies—materials that are pre-impregnated with resin—that are tailored for automated manufacturing processes like automated tape laying (ATL) and automated fiber placement (AFP). These technologies are crucial for high-volume industries like automotive, where cycle times are measured in seconds, not hours. By designing materials that are inherently easier for robots to handle, Toray is effectively building the bridge that will allow carbon fiber to cross over from low-volume, high-performance sectors into the heart of mass production.

The competitive pressure from other global players is a significant catalyst. While Toray maintains a leading position, it faces formidable challenges from European firm SGL Carbon and U.S.-based Hexcel, each making their own strides in innovation. More notably, the rise of Chinese carbon fiber producers, backed by substantial state investment, is altering the global supply chain and price dynamics. This has compelled Toray to not only innovate faster but also to secure its technological lead through an aggressive intellectual property strategy and by forming deep, strategic partnerships with end-users. Its long-standing relationships with aerospace giants like Boeing are now being mirrored in the automotive world, with collaborations aimed at co-developing the next generation of carbon fiber components for electric vehicles.

The implications of this accelerated innovation are profound. For the aerospace industry, it means the next generation of aircraft will be even lighter and more fuel-efficient. For the automotive world, it heralds a future where electric vehicles can travel significantly farther on a single charge, directly addressing the critical issue of range anxiety. The ripple effects will be felt in wind energy, where longer, lighter, and stronger turbine blades can capture more energy, and in hydrogen storage, where high-pressure tanks made from advanced carbon composites are essential for the viability of a hydrogen economy. Toray's push is, therefore, not just a corporate strategy but a critical enabler for multiple global technological and environmental ambitions.

In conclusion, the accelerated pace of carbon fiber innovation led by Toray Industries represents a pivotal moment in materials science. It is a comprehensive effort that spans from the molecular chemistry of precursors to the digital orchestration of factories and the re-imagining of automated assembly lines. By systematically attacking the historical barriers of cost and manufacturability, Toray is transforming carbon fiber from a niche, high-performance material into a foundational element for a lighter, stronger, and more sustainable industrial future. The race is on, and the finish line is a world transformed by the properties of a fiber thinner than a human hair but stronger than steel.

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025